This is what I’m doing mostly. Developing a product, mechanism or a part, considering the fabrication technology, capabilities of equipment and options.

When you create a product, it goes through various stages, depending on managing: evaluation and planning, concept design, design for manufacturing and preparation. One step is inevitable – design of each part of the product. Design in a such way that it is feasible at manufacturing and optimal by costs.

I’m developing these parts keeping in mind the requirements of material, requirements and capabilities of manufacturing technology, possibilities of mechanism and its purpose. Each part needs to be manufactured properly, consistently in mass manufacturing, fit properly in assembly and do its job reliably.

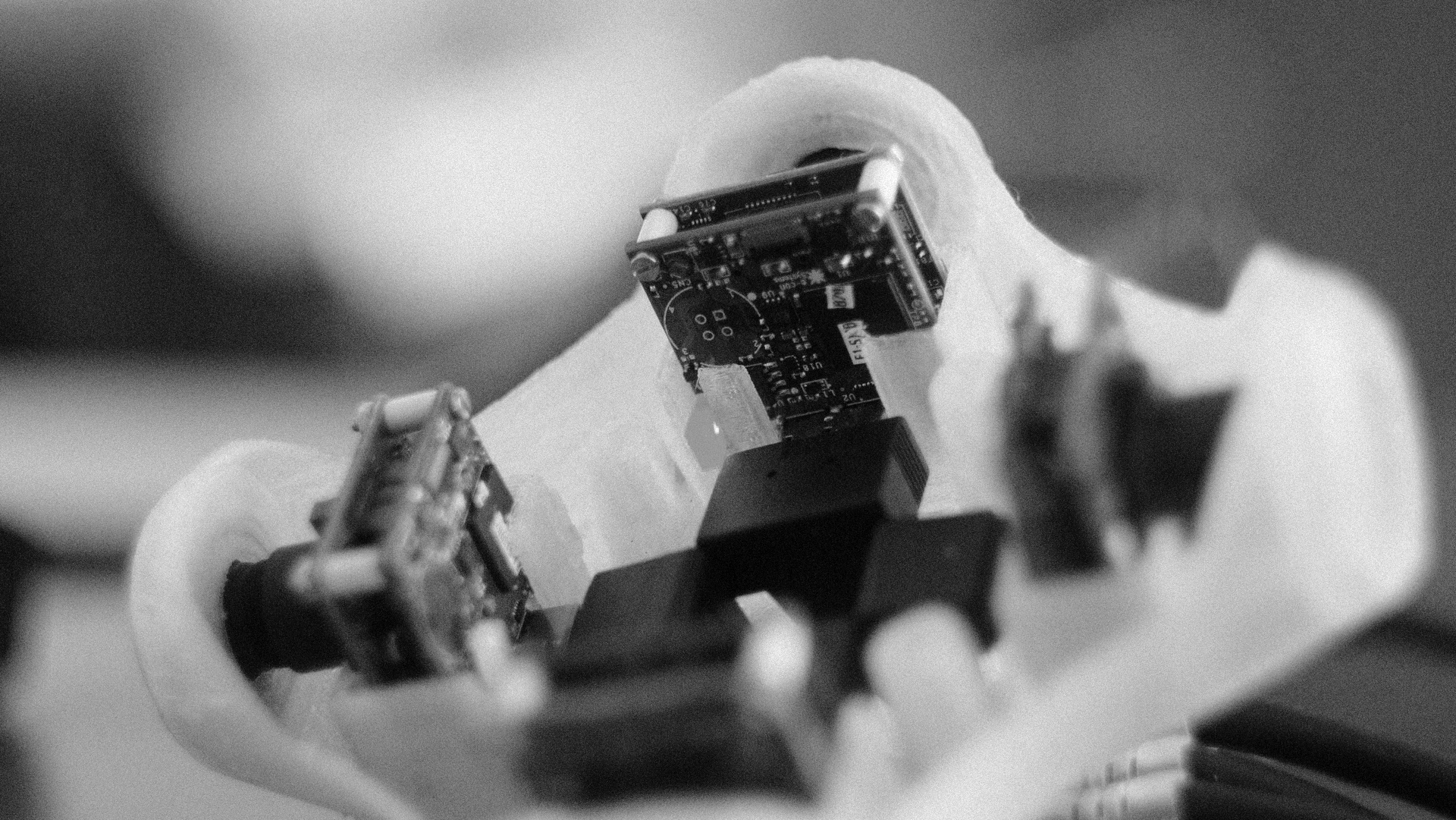

Prototyping is important phase in development of complex product. It lets us to find all the flaws of design, test the product and make sure that we’ve done everything to improve it.

Currently widely popular 3D printing technologies allow to make prototypes easily and with minimal expenses. Quality of printed parts may be sufficient even for demonstration prototype. And time to make the part is significantly shorter than any other prototyping method.

Often I’m printing prototypes on my own, to check how certain part fits, how convenient it is to interact with it, if it’s needed.

However, for some mechanisms we have to use metal parts processed at specialized workshop. It’s also an option during development for mass manufacturing.

I’ve worked with milling machines and other metal cutting equipment, manual and CNC. It is useful experience which allows me to understand producing approach and technology in general. I can adjust design of certain parts for effective machining and saving on material or processing time, understand priorities better.

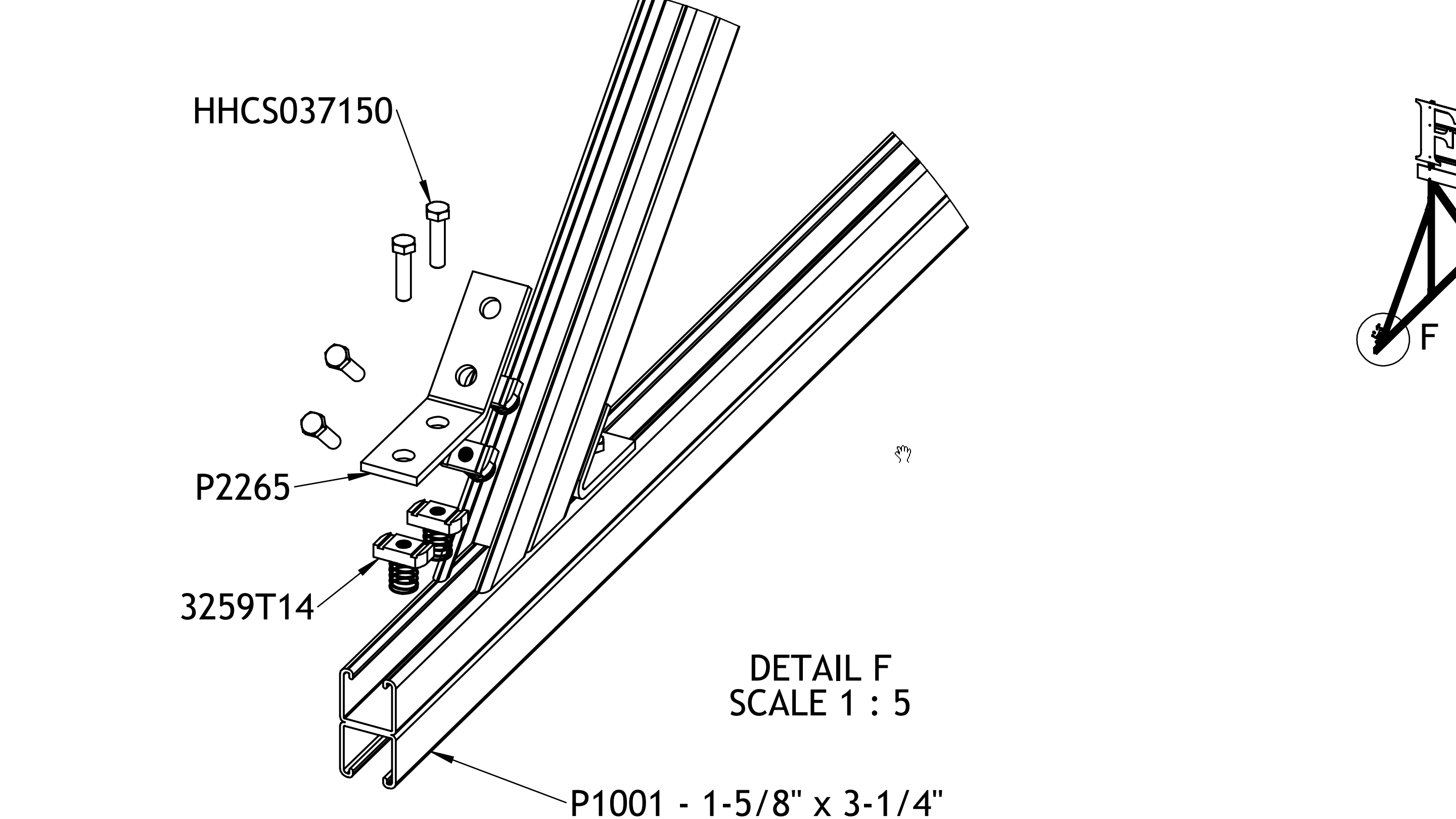

In my work I often use off-the-shelf parts and mechanisms. It is effective in many ways and for many applications. I always consider location of assembly site and local market to make sure that every part will be present at assembly. Mostly I’ve worked with North American region and Europe in terms of sourcing. Asian suppliers also, but it varies from time to time.

For any project I have individual approach because every team is different. Whether you already know exactly what you need or if you’re not sure where to begin, lets talk and we’ll find out how can we make the job done.